Basic Material For Plating

Product Details:

- Grade Standard Technical/Industrial Grade

- Packaging Type HDPE Bag/Drum/Container

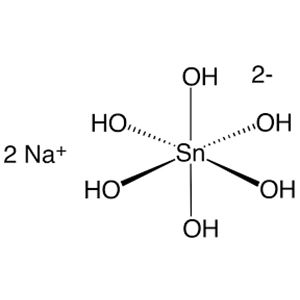

- Chemical Name Varies (commonly Nickel Sulphate, Copper Sulphate, Zinc Sulphate, etc.)

- Equipment Type Plating Raw Material

- Shelf Life 12 24 months

- Concentration Industry standard, varies per chemical (refer to technical datasheet)

- Temperature Range Ambient to 60C

- Click to View more

X

Basic Material For Plating Price And Quantity

- 100 Kilograms

Basic Material For Plating Product Specifications

- Basic Material For Plating

- Varies (commonly Nickel Sulphate, Copper Sulphate, Zinc Sulphate, etc.)

- 12 24 months

- Plating Raw Material

- Technical/Industrial Grade

- HDPE Bag/Drum/Container

- 4.0 7.0, depending on application

- Ambient to 60C

- N/A (material supplied in bags/containers)

- Customizable as per requirement

- Industry standard, varies per chemical (refer to technical datasheet)

Basic Material For Plating Trade Information

- 500000 Kilograms Per Year

- 30 Days

- Australia, Central America, South America, Eastern Europe, Middle East, Asia, Western Europe, North America, Africa

Product Description

Gain access to our polished Basic Material For Plating, offering instant savings with the lowest price from a crackerjack supplier. Specially crafted for electroplating, this prime material boasts a minimum purity of 98% (varies with selected chemical: Nickel Sulphate, Copper Sulphate, Zinc Sulphate, etc.), ensuring exceptional results in surface treatment. Available as powder, granules, or crystals, it is completely soluble in water for ease of use. Handle with personal protective equipment and store away from sunlight for extended shelf life. Tailor dimensions to your processrely on a trusted distributor from China for all industry-standard requirements.

Versatile Features & Wide Application Scope

The Basic Material For Plating delivers customized compatibility for various metals, thanks to its adaptable physical formspowder, granules, or crystals. Its complete water solubility ensures seamless integration into electroplating baths. Simply dissolve as directed in the technical datasheet to prepare your bath. Widely used in plating processes across automotive, electronics, and jewelry manufacturing, it enhances surface durability and finish quality. Always apply with proper safety gear for operator protection during handling and processing.

Payment Flexibility, Packaging, & Market Reach

Benefit from competitive rate options and favorable exchange terms for both domestic and international clients. This plating raw material is securely packaged in HDPE bags, drums, or containers, preserving its quality during storage and transportation. We serve the main domestic market and robust export market, ensuring timely distribution across global locations. As a trusted manufacturer and exporter, we guarantee regulated supply volumes tailored to customer requirements, dictated by project scale and local compliance.

Versatile Features & Wide Application Scope

The Basic Material For Plating delivers customized compatibility for various metals, thanks to its adaptable physical formspowder, granules, or crystals. Its complete water solubility ensures seamless integration into electroplating baths. Simply dissolve as directed in the technical datasheet to prepare your bath. Widely used in plating processes across automotive, electronics, and jewelry manufacturing, it enhances surface durability and finish quality. Always apply with proper safety gear for operator protection during handling and processing.

Payment Flexibility, Packaging, & Market Reach

Benefit from competitive rate options and favorable exchange terms for both domestic and international clients. This plating raw material is securely packaged in HDPE bags, drums, or containers, preserving its quality during storage and transportation. We serve the main domestic market and robust export market, ensuring timely distribution across global locations. As a trusted manufacturer and exporter, we guarantee regulated supply volumes tailored to customer requirements, dictated by project scale and local compliance.

FAQs of Basic Material For Plating:

Q: How should I store the Basic Material For Plating to maintain its quality?

A: Store the material in a cool, dry location away from direct sunlight to preserve its integrity and prolong shelf life. Use original HDPE packaging.Q: What is the benefit of using this plating material in electroplating applications?

A: With a minimum purity of 98%, this material ensures consistent surface enhancement, optimal conductivity, and durable plating results suitable for a wide range of metals.Q: Where can this basic material be applied?

A: It is suitable for use in surface treatment and electroplating processes within automotive, electronics, jewelry, and hardware manufacturing industries.Q: How is the application process carried out?

A: Dissolve the powder, granules, or crystals in water per technical guidelines to prepare the electroplating bath. Follow recommended concentration and pH for best performance.Q: What safety measures should be taken during usage?

A: As the material is hazardous, always handle with appropriate personal protective equipment, including gloves, goggles, and protective clothing, to ensure operator safety.Q: When does this product need to be replaced?

A: The shelf life ranges from 12 to 24 months depending on storage conditions and chemical type; check the expiration before each use for best results.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

: +8613554014698

: +8613554014698 Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese